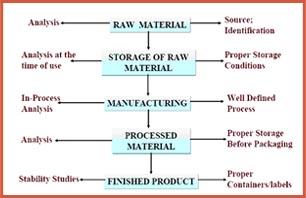

Production

- Raw Material Analysis.

- In- process Analysis.

- Finished Product analysis.

- Microbial Analysis & Heavy Metal Test.

- Active ingredient analysis by HPLC.

- HPLC, GC techniques are used to analyze samples qualitatively and quantitatively.

- HPTLC testing facility can be availed on the specific request of the customer

The Manufacturing facility is GMP (Good Manufacturing Practices) certified facility. The manufacturing process involves the procurement of raw herbs through raw material analysis, production and finished product analysis.

Our Manufacturing Facilities

- We are well equipped to manufacture various extracts of aqueous and solvent base.

- We have an installed capacity to process around 60-100 MT of raw herb.

- 100 MT to 150 MT of output per Month.

- Option to increase the production capacity available.

- All our equipments are designed in Stainless steel.

- Calendria (Falling film evaporator) has been installed for distillation under vacuum.

- We have 48 tray drier and 30 tray Vacuum Shelf Tray drier for drying the products

- Our Plant is designed as per GMP standards.

- Maintaining all the quality parameters as per the WHO guidelines.

- Clean room data maintained.

Our Manufacturing Facilities